Aws Visual Inspection

Defect Type Defect Description/ Visual Appearance Was this type of Defect Found during the Audit? # of Defects Found or Total Defective Length of Weld in (in/mm) Sketch/Photo Typical Causes NCO's Cracks (Longitudinal or Transverse) Cracks are defined as fracture-type discontinuies characterized by a sharp tip and high ratio of length. To more explanation about Visual Inspection Acceptance Criteria you can open AWS D1.1 section 6 (inspection) part C. Before you inspect and make decision about weld as per AWS D1.1, you must know definitions of: 1. Statically Loaded Nontubular Connections (more detail see Section 2 part B AWS.

- Aws Visual Inspection Standard

- Weld Inspection Aws

- Aws Visual Inspection Report Form

- Aws Visual Inspection Criteria

A 15-hour seminar on the inspection of welding under the American Welding Society’s Structural Welding Codes:

Aws Visual Inspection Standard

- AWS D1.1 – Steel,

- AWS D1.3 – Sheet Steel,

- AWS D1.4 – Reinforcing Steel, and

- AWS D1.8 – Seismic Supplement

Welding Nomenclature

- Joints, welds, position, metallurgy

Welding Processes and Filler Metals

- SMAW, FCAW, GMAW, SAW, GMAW-S, GTAW, ESW, EGW

- Matching filler metals

- AWS A5 identification systems

- Storage and exposure limitations

Welding Procedure Specifications

- Evaluation and use of WPSs

- Preheat and interpass temperatures

- Prequalification limits

- Welding procedure qualification

Weld Joint Details – Structural Steel

- Prequalified groove weld details

- Qualification of joint details

- Weld backing and weld tabs

- Weld access holes, copes and reentrant corners

- Plug and slot welds

Fabrication

- Welding equipment and environment

- Joint preparation and fit-up

- Thermal cutting processes and quality

- Distortion control

- Dimensional tolerances

Welding Personnel Qualification

Weld Appearance and Quality

Weld Inspection Aws

- Acceptance criteria options

- Weld discontinuities

- AWS D1.1 quality criteria

- Repairs

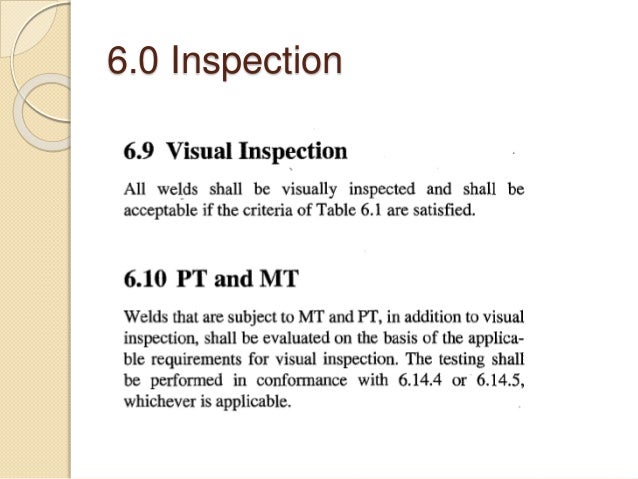

Inspection and Nondestructive Testing

- Observation under AWS D1.1 and AISC

- Visual inspection

- Nondestructive testing methods and criteria – PT, MT, UT, RT

- Extent of NDT under AWS D1.1 and AISC

Welding Symbols

Tubular Joints

- Terminology and joint types

- Groove weld joint details

Fatigue Life Enhancement

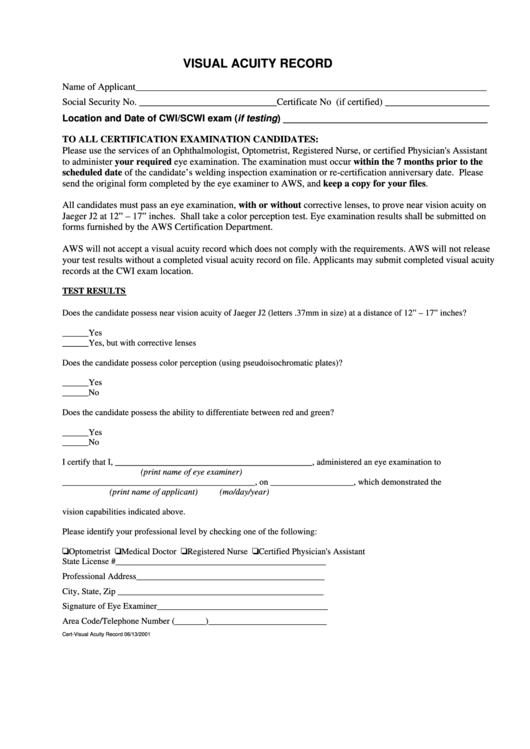

Aws Visual Inspection Report Form

- TIG dressing, burr grinding, toe peening, ultrasonic methods

AWS D1.8 Structural Welding Code – Seismic Supplement

- Welding materials – strength, toughness, intermixing, testing

- WPS and technique limitations

- Connection details

- Protected Zones and repairs

AWS D1.3 Structural Welding Code – Sheet Steel

- Joints

- WPS and welding personnel qualification

- Weld quality

AWS D1.4 Structural Welding Code – Reinforcing Steel

Aws Visual Inspection Criteria

- Joints

- WPS and welding personnel qualification

- Weld quality